Ichor Systems

Production Facility

-

< £2m

-

37,651ft2

-

20 weeks

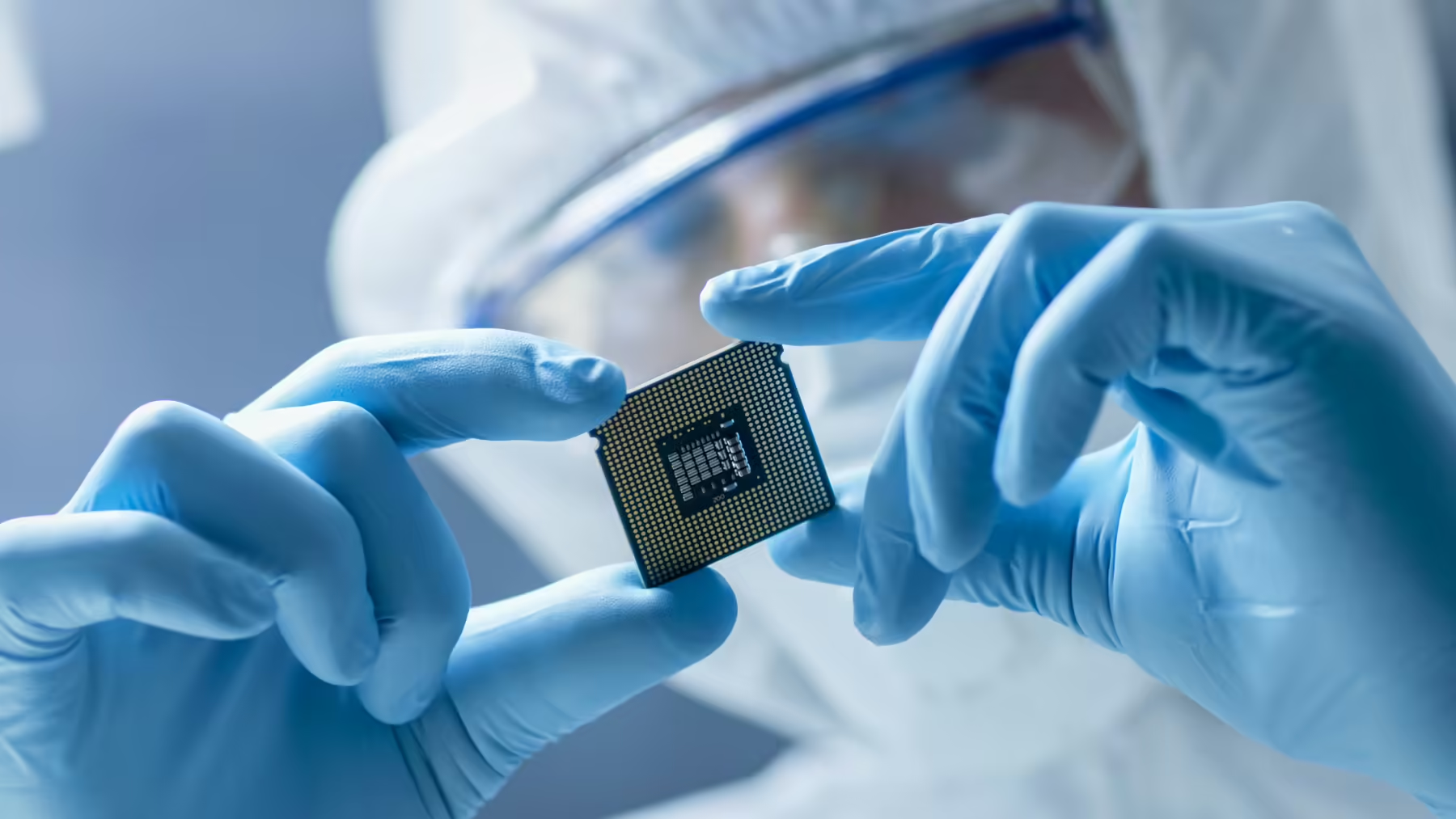

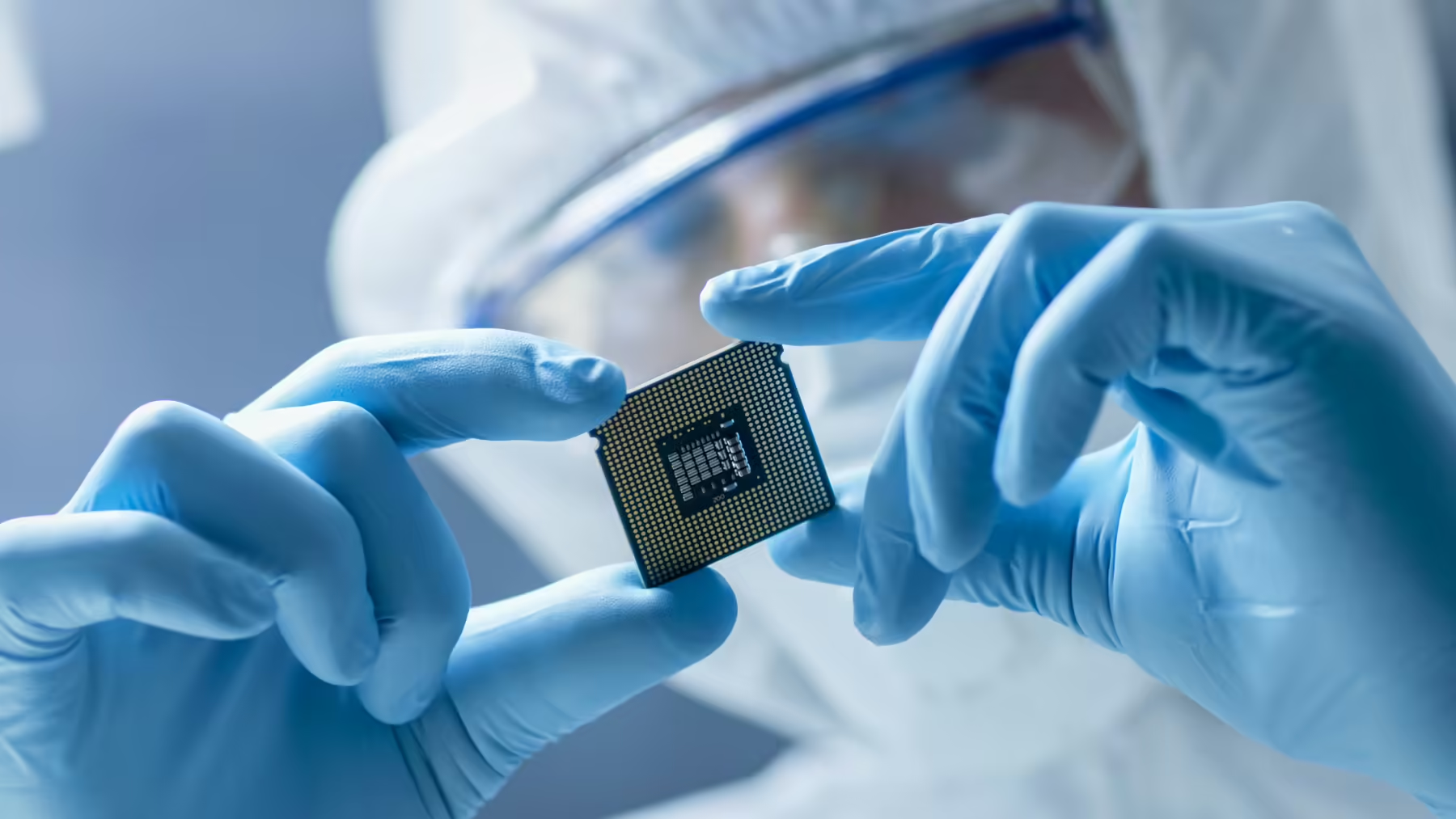

Ichor Systems is a global leader in the design, engineering, and manufacturing of critical fluid delivery subsystems and components for semiconductor capital equipment.

As a critical services turnkey partner to major original equipment manufacturers, Ichor’s customer base are able to outsource all non-critical elements of their tool design, production and support in order to focus their resources on process and technology development. The company which operates from seven key strategic sites globally possesses deep experience in managing rapid product introductions, worldwide supply chain networks, scheduling flexibility and exacting production quality standards.

Ichor Systems made the decision to move the Scottish manufacturing arm of its business to new 37,651ft2 facilities at Hamilton International Park in order to dramatically increase production capacity. After a competitive tender process, T-SQUARED was awarded the full turnkey design, construction and validation project consisting of four large clean, controlled areas.

The new facility, which required an extensive fit-out program due to the high-specification cleanroom requirements of the semiconductor industry, secured the future of Ichor’s existing staff. T-SQUARED subsequently designed and built a state of the art manufacturing facility which in turn has enabled production to be tripled since it opened.

"I would like to thank Alan Simpson and his team at T-SQUARED for delivering the high specification cleanroom facility ahead of schedule."