University of Glasgow, Gladd Laboratory

Next-generation technology

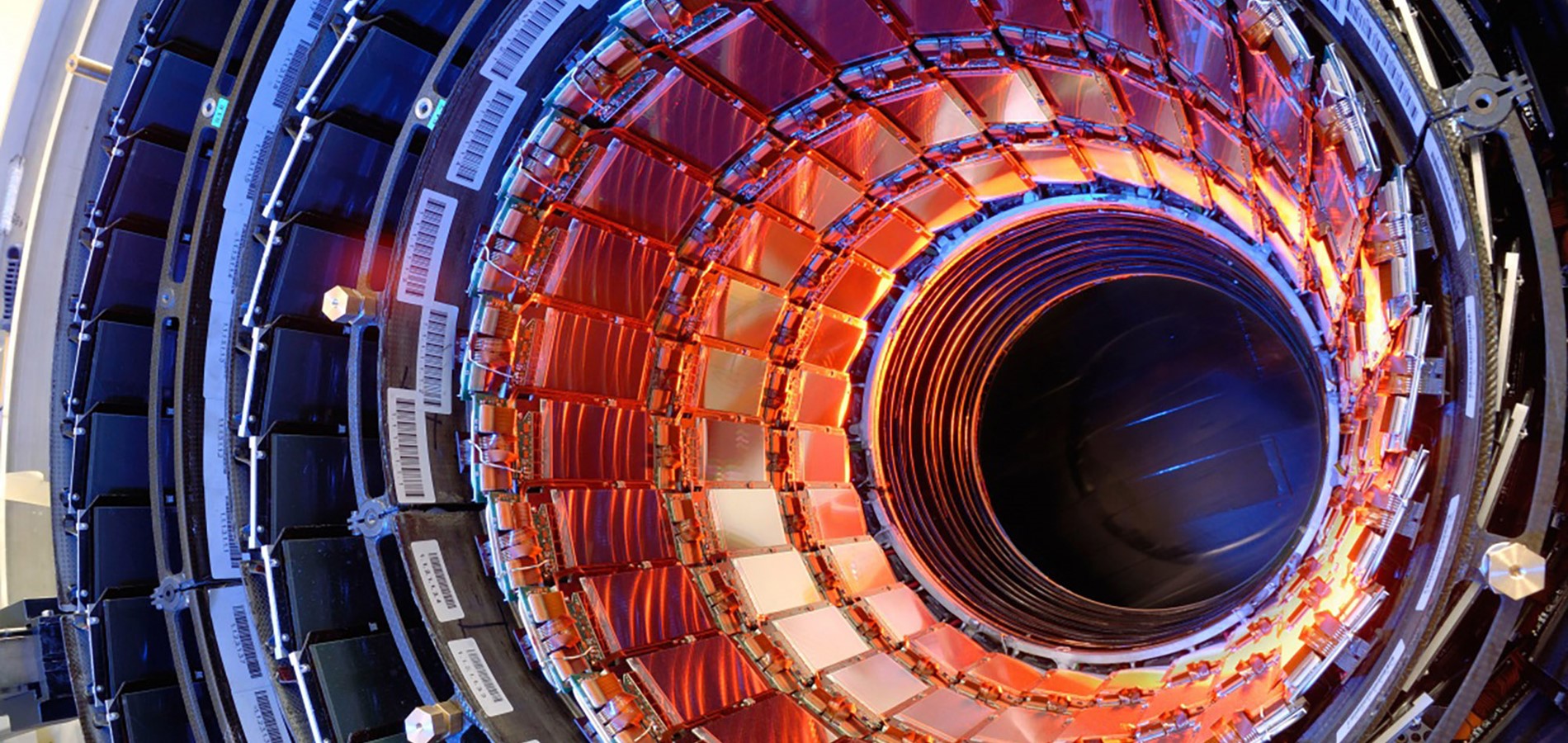

The University’s Glasgow Laboratory for Advanced Detector Development (GLADD) will allow scientists to continue developing their work assisting the CERN lab in Switzerland as well as having commercial applications such as medical imaging and airport security.

GLADD, based in the Kelvin Building, will be used by particle physicists who worked for more than 20 years in the development and construction of the semiconductor trackers in ATLAS, one of the detectors at CERN’s Large Hadron Collider (LHC) in Geneva.

Scope of the project

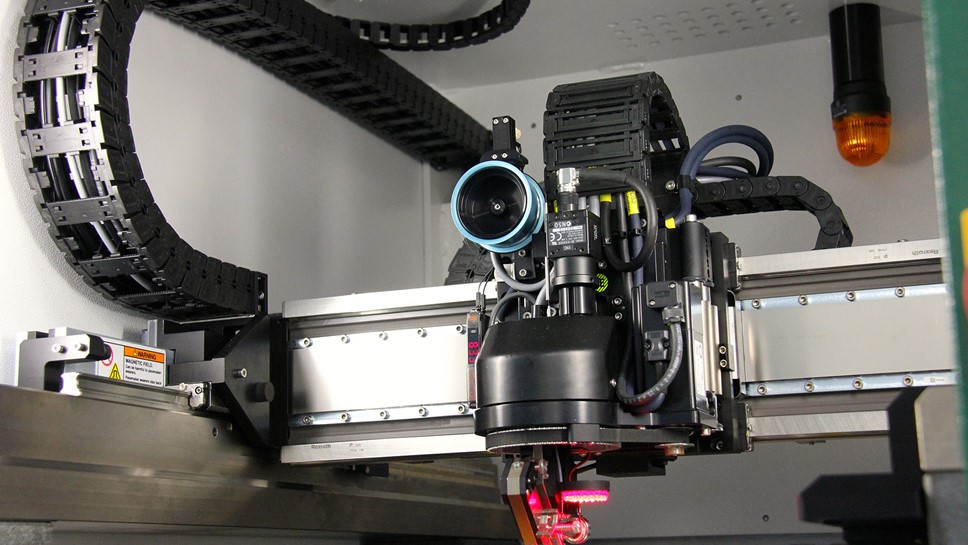

The new cleanroom laboratory - where air quality, temperature and humidity are highly regulated to protect sensitive equipment from contamination - contains a suite of cutting-edge equipment including an ultrasonic fine pitch wire bonder to fabricate interconnects in electronic chips and a probe station to investigate the functionality of improved sensor designs.

After a competitive tender, T-SQUARED was awarded the refurbishment and conversion of the space within the Kelvin Building into the cleanroom and change area.

The full scope of the project is as follows:

- Design work

- Management and coordination of all site works

- Mobilisation and demobilisation

- Fabric Installation works

- Supply & installation of HVAC works as per design

- Control and electrical works

- Installation of pipework systems

- Co-ordination of all fabric mechanical and electrical works

- Testing and commissioning

- Cleanroom validation

Specific project requirements

- Lining, rearrangement and installation of various walls and doors to enable Room 346 to function as a cleanroom and change area within the Kelvin Building of University of Glasgow

- The installation of new fabric walls and linings, windows, doors, ceilings and floors to clean area specifications

- The installation of new packaged air conditioning units and HEPA filters to serve the cleanroom and change area to give the temperature and air requirements as follows:

- a. The clean area requirement is for Class 10000

- b. Temperature controlled to 20 deg C +/- 2 deg C and 40-60% RH

- c. Room pressure - Cleanroom positive to change area

- d. Room pressure - Change area positive to corridor

- The installation of lighting and power to the Cleanroom and change areas to give a lighting level to 500 lux